Today I spent A LONG time measuring, remeasuring, adjusting, then remeasuring, double checking, etc...

The result: The axle is positioned under the truck. WB is 110. 22 " frame height at ride height. Caster is at a *rough* 3 degrees. That will be adjusted finally when the truck is done, at a shop.

Then, I welded it to the frame with scrap. Well, strong tack welds.

Then, I put the driver hub together, and mounted a tire to check for clearance, and just to get a feel for how things will look. Even stuck a CO in there to look at where I've tenatively placed link mounts in the calculator, and see how CO fits around the other junk.

The shock is at 1/2 travel in this pic. Ultimately, it will come down a bit, with hopefully a 60/40 down/up ratio.

Here is where the tire sits:

Approach will be halfway decent:

Floor shot to show the total drop. About 4.5"

My garage is short, I wanted to get a front shot, but this is about all I got. At full lock, the tire will hit that front body mount, so off they come.

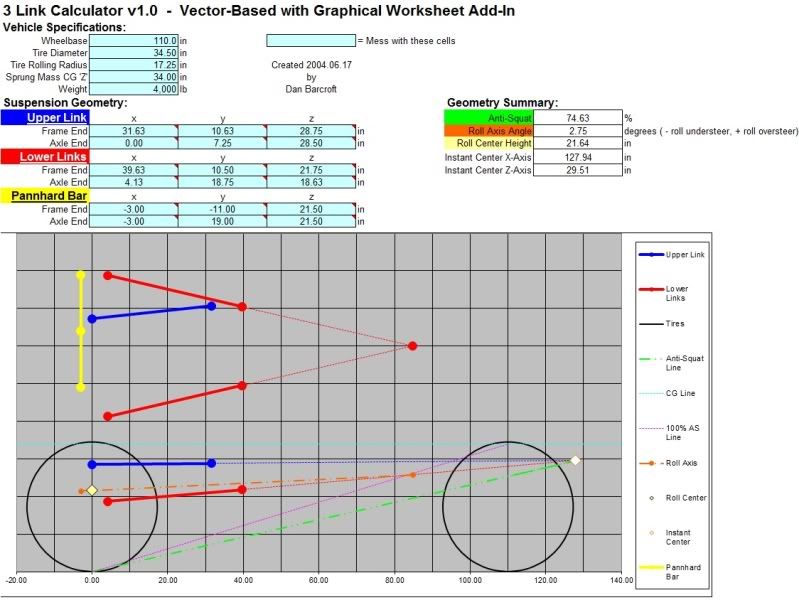

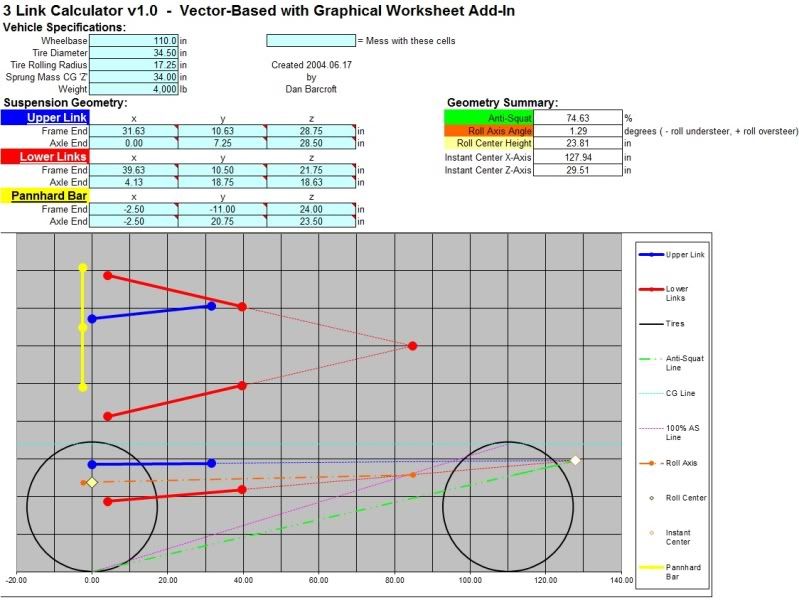

After that I started measuring out and designed the brackets for the lower link crossmember. Tomorrow, I'll cut them out and get that mounted into the truck. Then finalize the numbers in the calculator, check that things fit, and start building link mounts.

Reply With Quote

Reply With Quote